The world leader in application-specific connector and cable design solutions.

Onanon’s Product Lines

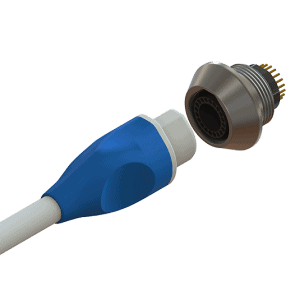

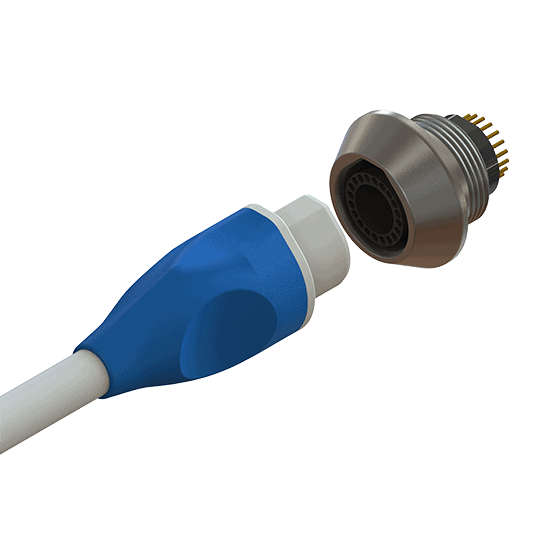

CustomConnect®

Custom Interconnect Solutions

CustomConnect is an interconnect that can be custom-made to your specifications. We can design an interconnect solution for a variety of industries and applications, from heart pumps and electrosurgical devices to agricultural equipment and aerospace technology, and much more.

View Product

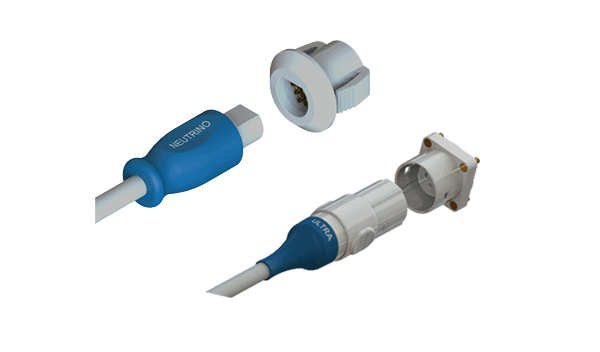

CableConnect®

Custom Cable Assemblies

CableConnect is a customizable or build-to-print cable assembly solution designed for your exact product requirements. We can design cable assemblies for a range of applications, including in hospital settings, wearable military equipment, and other harsh industrial environments.

View Product

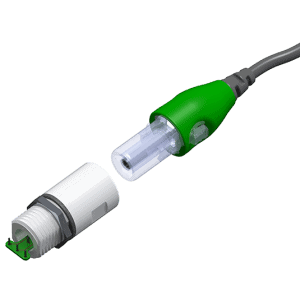

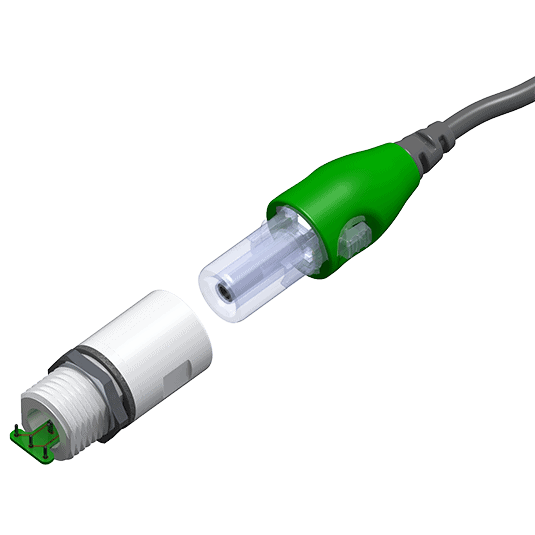

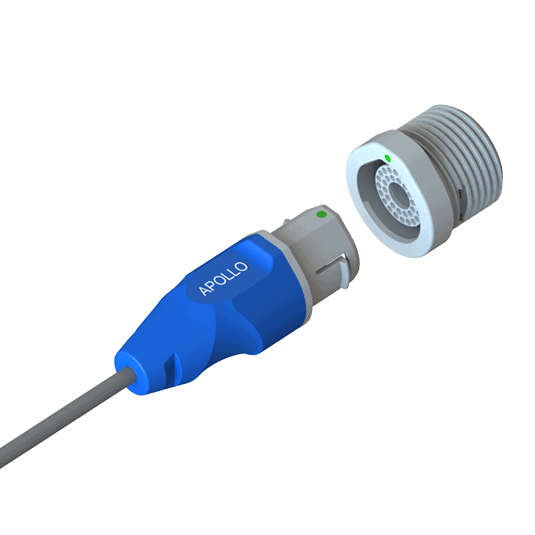

MagConnect®

Innovative Magnetic Cable Connector

MagConnect is the most intuitive interconnect in the world. With its patented magnetic, self-mating feature that makes it safe and easy to use, it can be designed for a variety of applications, including ultrasound devices, surgical equipment,and electric bikes and scooters.

View Product

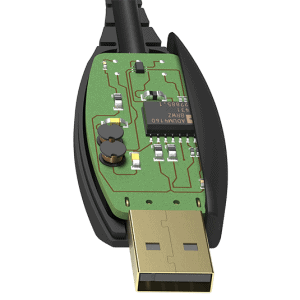

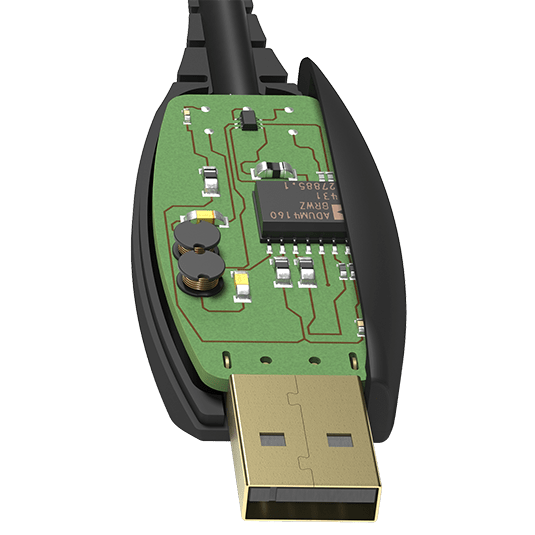

SmartConnect®

Innovative Smart Connectors

SmartConnect is an application specific interconnect that can be custom made with embedded electronics, allowing for digital scalability at the connector and cable level. We can design an intelligent interconnect for many applications, including electrosurgical devices with integrated device recognition, to smart electromechanical agricultural equipment.

View Product

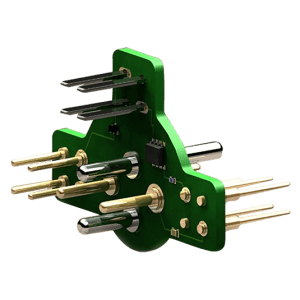

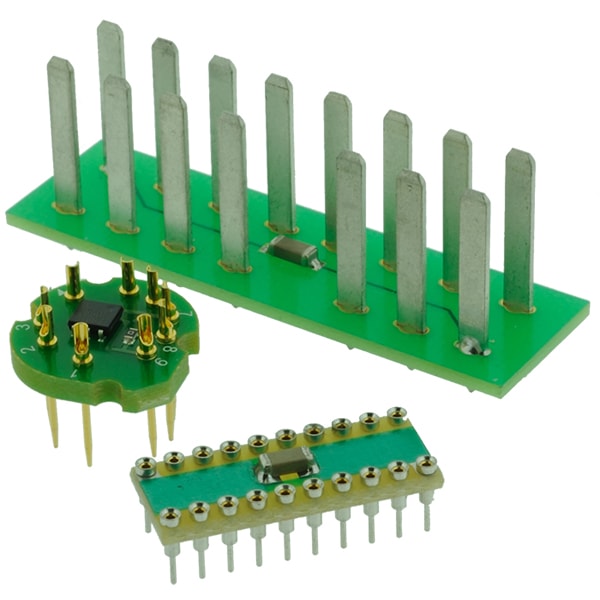

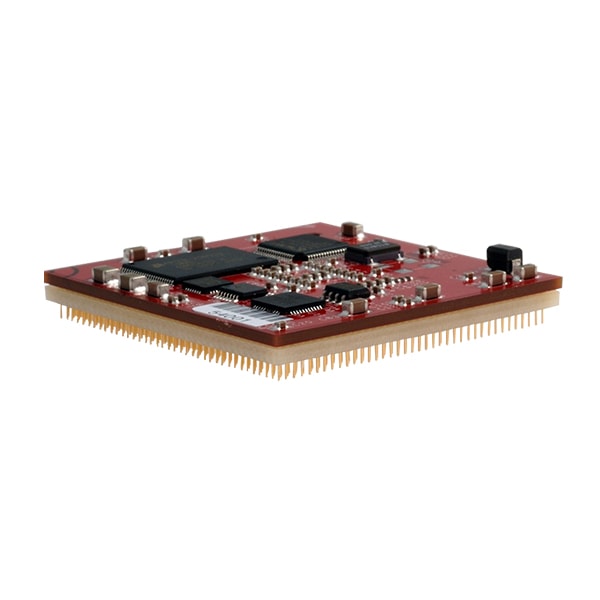

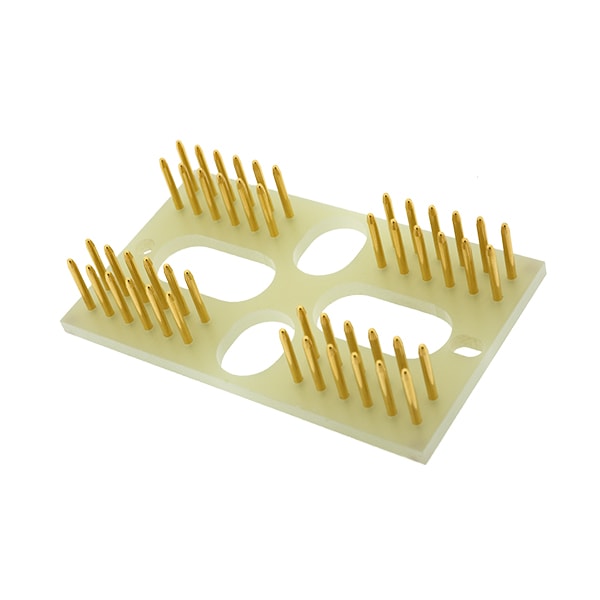

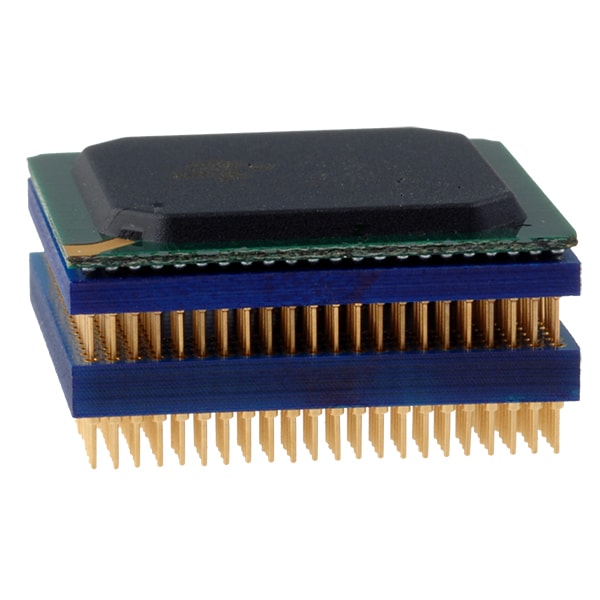

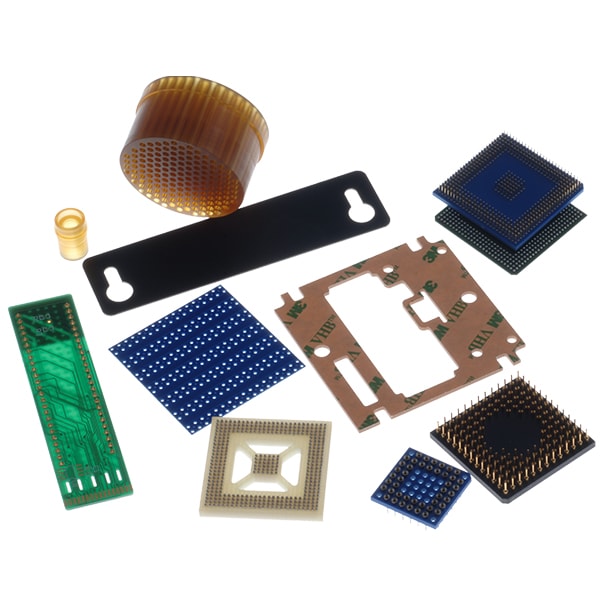

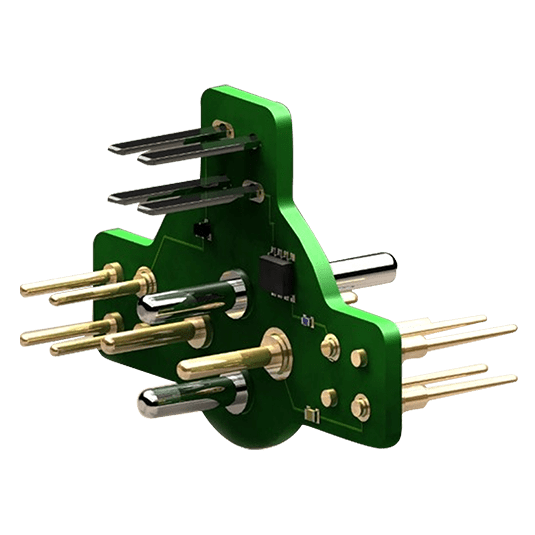

BoardConnect®

Custom Board to Board Connectors

BoardConnect solutions include PCBA to PCBA, PCBA to cable, PCBA to sensitive components, and many other board to board or board to cable connectors that can be designed in any form factor and with capabilities for embedded electronics. Often found in smart tractors, sensitive CCD and CMOS sensors, and more.

View Product

Off the Shelf

Connectors & Cable Assemblies

Onanon is a world leader in manufacturing application-specific connectors and cable assemblies. With decades of experience, we’ve mastered the craft of creating custom-made assemblies specifically designed for customer requirements and specifications. Additionally, we have a full catalog of innovative off the shelf options that are well suited for a variety of applications, as well as the manufacturing capabilities to quickly produce them in large quantities.

View Product

onanon’s Certifications: ISO Certified, ITAR Compliant, & More

onanon markets served

Onanon’s products lines can be found helping our customers involved in many different markets. Interested in learning more about how our products and how they can be adapted to your company's industry?